3D Printing in Automotive Industry is a game-changer, reshaping the way cars are built and designed. Step into a realm where innovation meets functionality, where every layer of plastic holds the promise of a better, faster, and more efficient future.

From revolutionizing automotive manufacturing to enhancing design processes, 3D printing is paving the way for a brighter tomorrow in the automotive industry.

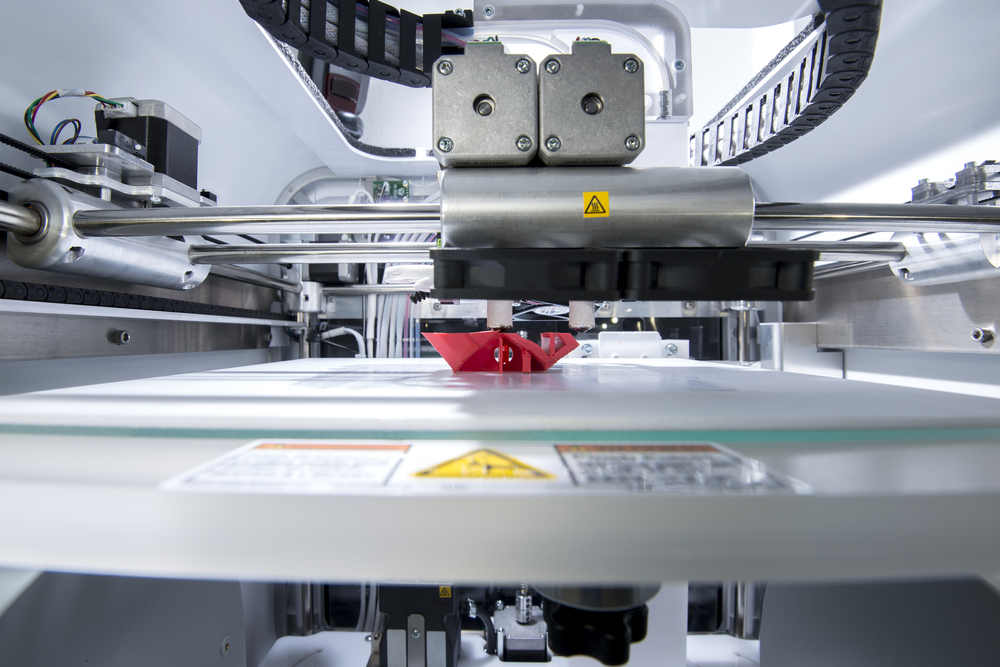

3D printing has become a game-changer in the automotive industry, revolutionizing the manufacturing process by offering numerous benefits and opportunities for innovation. This cutting-edge technology is transforming the way cars are designed, developed, and produced, leading to significant advancements in efficiency, customization, and cost-effectiveness.

Enhanced Design Flexibility

- 3D printing allows for the creation of complex and intricate designs that would be impossible or extremely challenging to achieve using traditional manufacturing methods.

- Automotive engineers can now design lightweight yet durable components that optimize performance and fuel efficiency, leading to the development of next-generation vehicles.

- Examples of 3D printed components in cars include engine parts, interior trim pieces, custom dashboard elements, and even entire vehicle prototypes.

Cost-Effective Production

- By eliminating the need for expensive tooling and molds, 3D printing reduces production costs and lead times, making it a cost-effective solution for small batch or customized manufacturing.

- Automakers can easily iterate designs, make quick modifications, and produce parts on-demand, streamlining the production process and reducing wastage.

- This flexibility in production enables automotive companies to respond rapidly to market demands, stay ahead of competitors, and deliver innovative solutions to customers.

Sustainable Manufacturing

- 3D printing promotes sustainability in the automotive industry by minimizing material waste, energy consumption, and carbon emissions during the manufacturing process.

- Using recyclable materials and additive manufacturing techniques, car manufacturers can produce components with reduced environmental impact, contributing to a greener and more sustainable future.

- Furthermore, the ability to repair and replace parts through 3D printing prolongs the lifespan of vehicles, reducing overall waste and promoting a circular economy within the automotive sector.

Applications

3D printing has revolutionized the automotive industry by offering innovative solutions in design and production processes. Let’s explore how this cutting-edge technology is transforming the way cars are designed and manufactured.

Comparing traditional automotive design methods

- Traditional methods: In the past, automotive design relied heavily on manual labor and machining processes, which were time-consuming and costly.

- 3D printing applications: With 3D printing, designers can create complex geometric shapes and intricate designs with precision, reducing the overall production time and costs significantly.

- 3D printing allows for rapid prototyping and iteration, leading to faster innovation and product development in the automotive industry.

How 3D printing is used in prototyping and customizing car parts

- Prototyping: 3D printing enables the creation of physical prototypes quickly and cost-effectively, allowing designers to test different iterations and designs before finalizing the product.

- Customization: Automotive companies can now offer customized car parts to meet individual customer preferences, thanks to the flexibility and versatility of 3D printing technology.

- 3D printing also allows for on-demand production of spare parts, reducing inventory costs and lead times for replacement components.

Challenges and limitations

- Material limitations: While 3D printing offers a wide range of materials to work with, not all materials are suitable for automotive applications due to factors like durability, heat resistance, and performance requirements.

- Scalability: Scaling up 3D printing for mass production of automotive parts can be challenging, as the technology may not yet be optimized for high-volume manufacturing.

- Quality control: Ensuring the quality and consistency of 3D printed parts in automotive design poses a challenge, as the technology is still evolving in terms of standards and regulations.

Materials Used

3D printing in the automotive industry has revolutionized the way car parts are designed and manufactured. The materials used in 3D printing play a crucial role in determining the performance, durability, and efficiency of automotive components.

Types of Materials

- 1. Polymers: Polymers such as ABS, PLA, and nylon are commonly used in 3D printing for automotive applications. These materials are lightweight, flexible, and cost-effective, making them ideal for prototyping and producing interior components.

- 2. Metals: Metals like aluminum, titanium, and stainless steel are utilized for 3D printing metal parts in the automotive sector. These materials offer high strength, heat resistance, and durability, making them suitable for producing engine parts, exhaust systems, and structural components.

- 3. Composites: Composite materials, including carbon fiber and fiberglass, are increasingly being used in 3D printing for automotive applications. These materials combine the strength of fibers with the flexibility of polymers, resulting in lightweight yet robust parts.

Properties and Suitability

- Strength and Durability: Metals are preferred for parts that require high strength and durability, such as engine components and chassis parts.

- Heat Resistance: Materials like aluminum and titanium are chosen for parts exposed to high temperatures, like exhaust systems and turbochargers.

- Lightweight: Polymers and composites are ideal for producing lightweight components, reducing the overall weight of the vehicle and enhancing fuel efficiency.

Advancements in Material Science

Advancements in material science have led to the development of new materials specifically designed for 3D printing in the automotive industry. These materials offer improved mechanical properties, thermal stability, and chemical resistance, expanding the possibilities for creating complex and high-performance car parts. Researchers are also exploring the use of sustainable materials and bio-based polymers to reduce the environmental impact of automotive manufacturing processes.

Future Trends and Innovations

3D printing technology is continuously evolving, bringing about exciting innovations and trends in the automotive industry. Manufacturers are exploring new ways to leverage the capabilities of 3D printing to revolutionize the way cars are designed, produced, and perform on the road.

Customization and Personalization

- 3D printing allows for intricate customization and personalization options in automotive design. From personalized interior components to unique exterior features, manufacturers can cater to individual preferences like never before.

- Customized 3D printed parts can enhance the overall driving experience, providing both aesthetic appeal and functional benefits tailored to the driver’s specific needs.

Lightweighting and Material Innovation

- One of the key trends in 3D printing for the automotive industry is lightweighting. By utilizing advanced materials like carbon fiber-reinforced polymers and metal composites, manufacturers can create lightweight yet durable components that improve fuel efficiency and overall performance.

- 3D printing enables the production of complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods, leading to innovative designs that optimize strength-to-weight ratios.

On-Demand Spare Parts Manufacturing

- With the adoption of 3D printing, automotive companies can establish on-demand spare parts manufacturing processes. This allows for the rapid production of replacement components, reducing lead times and inventory costs while ensuring a steady supply of parts for vehicle maintenance and repairs.

- By decentralizing spare parts production through 3D printing, manufacturers can streamline logistics and improve customer satisfaction by offering quick and efficient solutions for part replacements.

In conclusion, 3D Printing in Automotive Industry is not just a technological advancement; it’s a glimpse into the limitless possibilities of what the future holds for cars and transportation. As we embrace these innovations, we embark on a journey towards safer, more sustainable, and incredibly dynamic vehicles that will shape the roads of tomorrow.