Robotic Process Automation in Manufacturing sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with inspirational narrative language style and brimming with originality from the outset.

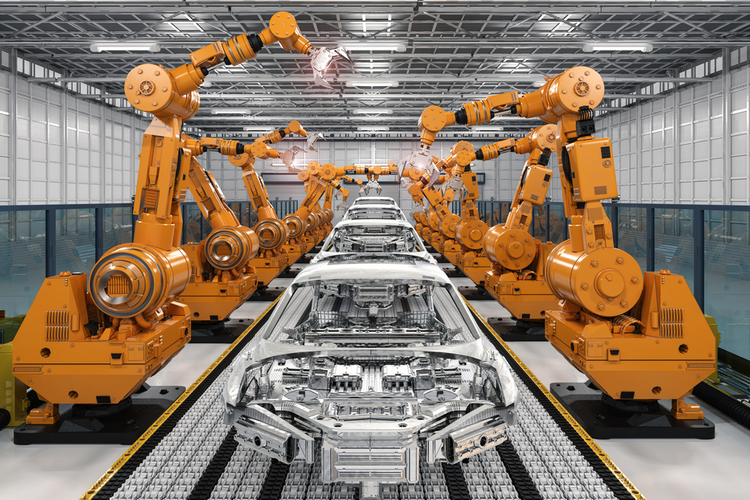

In the realm of manufacturing, the integration of Robotic Process Automation (RPA) has revolutionized traditional processes, paving the way for increased efficiency, reduced errors, and enhanced productivity. Let’s delve into the transformative impact of RPA in the manufacturing sector.

Robotic Process Automation (RPA) plays a crucial role in revolutionizing the manufacturing industry by improving efficiency, reducing errors, and enhancing productivity.

Improving Efficiency

RPA streamlines manufacturing processes by automating repetitive tasks such as data entry, monitoring, and reporting. This not only saves time but also ensures consistent and accurate results, ultimately leading to increased efficiency in production.

Reducing Human Errors

One of the significant advantages of RPA in manufacturing is its ability to minimize human errors on production lines. By eliminating manual intervention in critical processes, RPA ensures precision and reliability, resulting in higher quality output and reduced wastage.

Enhancing Productivity

With RPA handling mundane and repetitive tasks, manufacturing personnel can focus on more strategic and value-added activities. This shift in focus boosts overall productivity as employees can dedicate their time and expertise to tasks that require human intervention, creativity, and problem-solving skills.

Applications

Robotic Process Automation (RPA) has revolutionized the manufacturing industry by automating various tasks, optimizing processes, and improving efficiency. Let’s explore some specific applications of RPA in manufacturing.

Automated Tasks in Manufacturing

- Automating repetitive assembly line tasks such as picking and placing components.

- Performing quality inspections on products using sensors and cameras.

- Monitoring equipment performance and maintenance schedules.

Streamlining Inventory Management

RPA plays a crucial role in managing inventory efficiently in manufacturing facilities. By automating inventory tracking, ordering, and replenishment processes, RPA helps in reducing errors, minimizing stockouts, and optimizing inventory levels. This leads to cost savings and improved operational efficiency.

Quality Control Processes

- RPA can enhance quality control processes on the production floor by conducting real-time inspections and identifying defects or deviations.

- Automating data collection and analysis for quality assurance purposes.

- Ensuring compliance with industry standards and regulations through automated checks and audits.

Challenges and Solutions in Implementing RPA in Manufacturing

Implementing Robotic Process Automation (RPA) in manufacturing comes with its own set of challenges that need to be addressed in order to ensure a successful integration. Manufacturers often face resistance from their workforce, encounter technical hurdles, and must prioritize cybersecurity measures when implementing RPA systems.

Resistance from Workforce

One of the common challenges in implementing RPA in manufacturing is the resistance from the existing workforce. Employees may fear that automation will replace their jobs or disrupt their daily routines. To overcome this resistance, it is crucial for management to communicate transparently with employees about the benefits of RPA. Highlight how automation can streamline processes, increase efficiency, and create new opportunities for upskilling and professional growth.

Technical Hurdles

Another challenge faced by manufacturers is dealing with technical complexities during the implementation of RPA systems. Integrating automation tools with existing machinery and software can be a daunting task. To overcome this challenge, it is essential to work closely with IT experts and RPA providers to ensure a seamless integration. Training employees on how to operate and troubleshoot RPA systems can also help in overcoming technical hurdles.

Cybersecurity Measures

Integrating RPA in manufacturing systems also brings about the importance of cybersecurity measures. With increased automation, there is a higher risk of cyber threats and data breaches. Manufacturers need to prioritize cybersecurity by implementing robust encryption protocols, monitoring systems for any suspicious activities, and conducting regular security audits. Investing in cybersecurity training for employees can also help in safeguarding sensitive data and maintaining the integrity of RPA systems.

Future Trends

Robotic Process Automation (RPA) is set to revolutionize the manufacturing industry in the coming years, with several key trends shaping its future.

AI Integration with RPA

AI integration with RPA is expected to further optimize manufacturing operations by enabling machines to learn from data, adapt to new situations, and make decisions without human intervention. This combination will enhance the efficiency and accuracy of production processes, leading to increased productivity and cost savings.

Impact on Workforce in Manufacturing Industries

The potential impact of RPA on reshaping the workforce in manufacturing industries is significant. While some repetitive tasks may be automated, new roles will emerge that require human oversight, creativity, and problem-solving skills. This shift will necessitate upskilling and reskilling of employees to adapt to the changing landscape of manufacturing operations.

Evolution of RPA Technologies

RPA technologies are expected to evolve rapidly, with advancements in machine learning, natural language processing, and cognitive automation. These technologies will enable RPA systems to handle more complex tasks, interact with unstructured data, and provide intelligent insights for decision-making in manufacturing scenarios. The applications of RPA are poised to expand beyond repetitive tasks to include strategic decision-making and predictive analytics.

As we conclude this exploration of Robotic Process Automation in Manufacturing, it becomes evident that the future of manufacturing is intricately intertwined with innovative technologies like RPA. Embracing these advancements not only streamlines operations but also propels industries towards a more automated and efficient future.